What is

Bio Turbo?

Bio Turbo is ethylene and airborne pathogens removal technology.

- Extends Storage Life

- Removes Ethylene

- Kills Bacteria & Viruses

- Prevents Mold & Fungi Build-up

- Decreases Odors

- Decreases Cross Contamination

Technology Overview

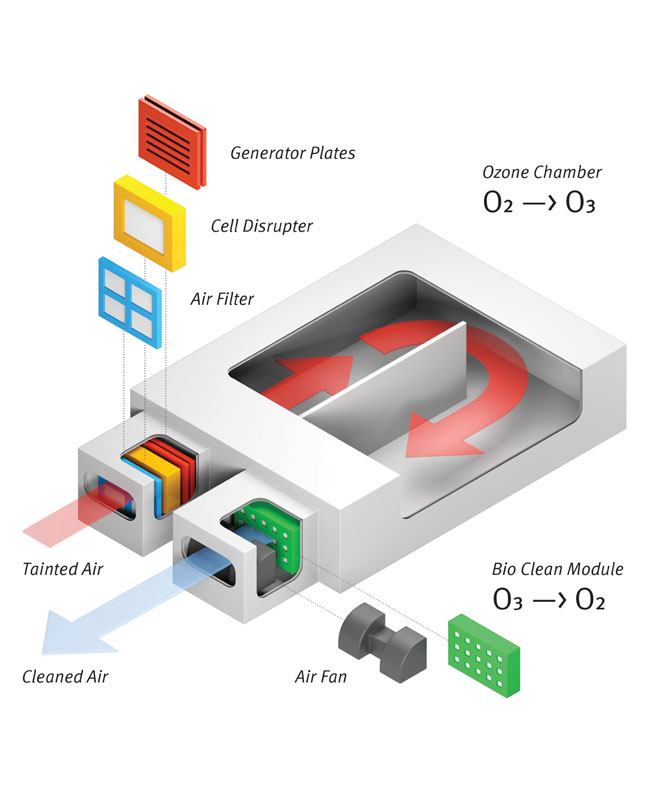

STAGE 1: AIR FILTER

The air filter removes dust and visual particles from the air.

STAGE 2: CELL DISRUPTER

An anti-microbial chemical is applied to the surface of a specially designed disrupter. It works by rupturing the outer membrane of the cells that make up these airborne pathogens. With efficiency rates of 99.5%+, this process stops their normal life development, thus destroying the cells.

STAGE 3: OZONE CHAMBER

This chamber uses the positive effects of ozone to eliminate ethylene gas. The ozone is safely contained within this chamber and not dispersed throughout the storage area.

STAGE 4: BIO CLEAN MODULE

In this final stage, a catalyst is used to change the ozone into clean oxygen. The catalyst creates a reaction that breaks down the ozone molecule. From here the clean oxygen is released back into the environment.

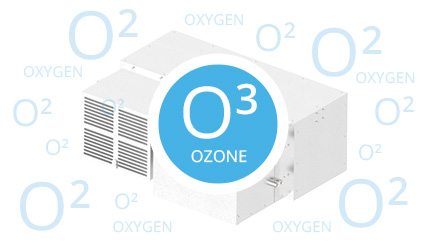

Completely Safe

Ozone is aggressive and exposure to ozone in high concentrations can be dangerous. However it’s not the case with Bio Turbo. Bio Turbo is the first technology to harness the power of ozone without exposing people or equipment to any risks, ozone is securely locked inside the reaction chamber and it never leaves the unit.

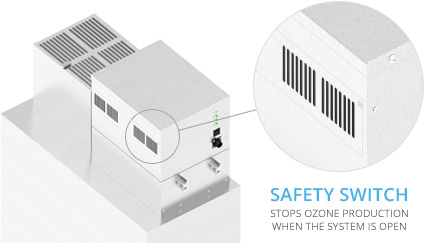

Security Measures

Safety switches automatically shut down ozone production in case there’s any problem with Bio Turbo components. This was done to make sure no ozone is ever released to the environment.

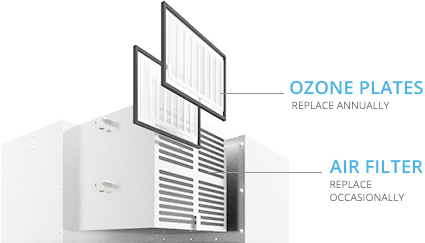

Low Maintenance

In comparison with competing technologies Bio Turbo is very maintenance friendly. It’s only necessary to replace air filters from time to time and ozone plates once per year and air. Replacing it is very easy and can be a person without any special technical background.

Patented Technology

Bio Turbo technology of employing ozone in a completely new way is unique in its kind and this is confirmed by patent issued by United States Patent and Trademark Office.

Comparison with Similar Technology

|

BIO TURBO

|

Potassium permanganate pallets

|

“NASA” technology

Special lights in combination

with a catalyst. |

Ozonating room

|

|

Active against |

Ethylene and airborne pathogens | Ethylene only | Ethylene and airborne pathogens | Ethylene and airborne pathogens |

Initial investment |

Average | Low | Relatively high | Relatively high |

Maintenance cost |

Low | High | High | High |

Maintenance labor |

Change air filter and ozone plates annually | Monthly check ups to find out if the pallets are still good. Replacing pallets 2 to 6 times per year as they expire, each pallets load is about 100 lbs. | Replacing special light bulbs annually | Trained personnel necessary for operating equipment |

Maintenance supplies |

Air filter and a set of ozone generating plates | 300 – 400 lbs of pellets for every system each year | A set of UV lamps | |

Safety considerations |

None | None | None | Exposure to ozone in high concentrations is dangerous |

Unit capacity |

One unit can cover up to 200,000 cubic feet in 24 hours | One unit covers up to 150,000 cubic feet | One unit covers up to 50,000 cubic feet |

Bio Turbo Applications

Different Models for Any Scale of Your Business

Bio Turbo uses power of ozone, a well-known technology applied in a completely unique way.