9 out of 10 apple growers and suppliers are completely wrong about this fact

Our findings show that up to 30% of apples may be lost to post-harvest waste*. Why?

Every experienced apple grower and supplier knows that investments made on storage are much more affordable than investments to increase crops.

The ideal storage conditions for apples cover:

• 0°C – 3°C temperature

• 90-95% humidity

• 0 ppm ethylene

• No airborne pathogens

While all cold storage owners address the first factor (temperature), most ignore the other factors, which are equally important and usually much more difficult to optimize.

*According to research of ”Waste and Resources Action Program“

How Miatech’s Bio Turbo reduces storage losses of perishables

Ethylene and airborne pathogens are common challenges which face most of the perishable distributors. Super Fresh Import Export company wasn’t an exception. Therefore, they installed the Bio Turbo system in each of their cold rooms.

As time passed, the quality of the stored fruits showed a significant lifespan improvement. “Specifically the apples stay firm for a much longer time, the grapes do not soften as fast, and there is less shatter (berries do not fall from the stern)”, said Sarot Assavapornchai, the company’s Managing Director.

Also, mold and airborne bacteria contaminations have been minimized since the customer began using the Bio Turbo. Overall there is less fruit smell in their cold rooms as well.

How much do you really lose, by not removing the ethylene from your cold room

Based on data collected from various Bio Turbo installations in apple storage cold rooms around the world, a box of apples at the beginning of the season was priced at $30, but after 3 months of storage, the price was just $26 due to the drop in quality. For an average apple storage cold room of 1000 cubic meters, this results in more than $18,000 in losses each season! The reason for such losses is the ethylene concentration in the cold room which makes apples ripen faster and lose firmness.

Bio Turbo is an effective technology for eliminating ethylene and airborne pathogens. With this equipment, our customers reported negligible changes in apple quality, therefore; there was no drop in the price. That helps them to save on average $120 per ton of apples every season. Thus, the common objection “I cannot afford this system” turns to “I cannot afford NOT having this system”.

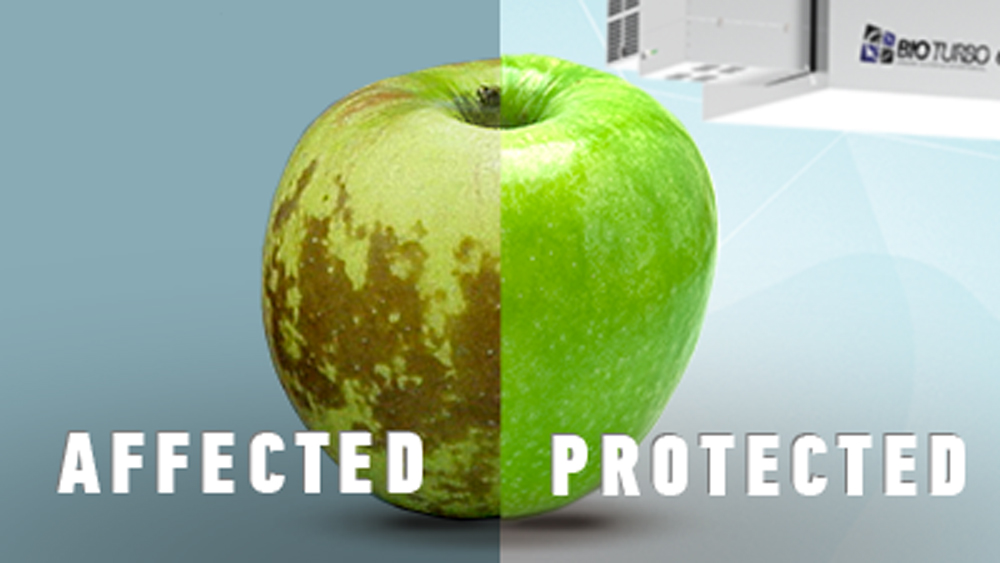

Reducing the ethylene can prevent superficial scald on stored apples

Superficial scald is a physiological disorder that causes brown patches on the skin of apples during their storage period. Scalded apples are still edible, but they can no longer be sold as a higher priced premium product. Most of them are supplied at a very low price to the apple juice business or to other processed food industries.

There are many factors that increase the risks of developing superficial scald. Early harvest, long storage periods and pre-harvest weather conditions are some of them. However, during the post-harvest storage period, ethylene gas is one of the most significant contributors of superficial scalding. Scientist have found that high ethylene levels increase the synthesis of the enzyme α-farnesene which is then oxidized and creates the discoloration on the skin. More information can be found at the website of Washington State University at the following link:

http://treefruit.wsu.edu/article/superficial-scald-management-in-apples/

The Bio Turbo is the most efficient ethylene and airborne pathogen removal system on the market.

How to cut apple post-harvest losses without costly investments?

Romanian apple grower, Octavian Dragan, stores his fruit in a cold room for an average of 8 months after harvest. Even though he maintains a low temperature (1–4°C), he still had to throw away around 25% of his apples.

This year he was able to save 80% of his previous losses. He says, it was due to installing Miatech’s Bio Turbo — an affordable technology that prevents mold and bacteria from spreading, and removes ethylene from the cold room air.

Octavian Dragan shared that even after 8 months of storage “the quality of the apples is great. They present themselves as fresh and have no deterioration.”